How to Make Your MRF Contract a Public-Private Win-Win

November 19, 2020

By Scott Mouw and Liz Bedard

The contract between a community-run recycling program and privately owned materials recovery facility (MRF) is one of the most impactful legal documents in the U.S. public recycling system. These contracts serve a critical purpose, ensuring that recycling programs remain sustainable over the long haul. Yet too often these contracts result in unintended problems – or, in the worst case, canceled recycling programs – because of practices that fail to accommodate both sides’ needs.

This is why The Recycling Partnership created the Guide to Community Material Recovery Facility Contracts. The comprehensive guide features best-management practices, including an overview of the MRF contracting process, case studies from communities, essential contract elements, and sample contract language to implement during your next contract negotiation.

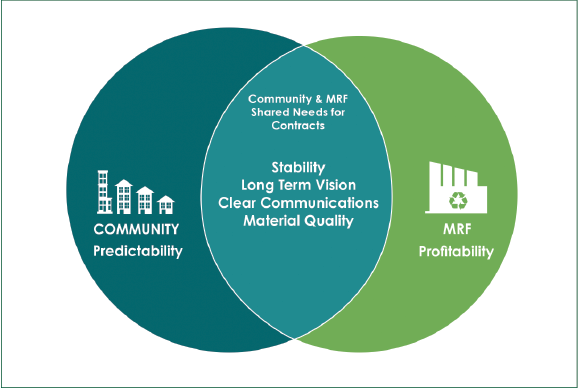

The best MRF contracts recognize the individual needs of each party while also grounding the agreement in their common goals, creating a true win-win outcome. Each party benefits from stability – the MRF to guarantee a return on expensive capital, and the community to keep services going. Each side also gains from a sense of trust, a shared vision, strong communication, and a coordinated commitment to material quality.

This guide is designed to help public recycling programs and MRFs develop transparent, balanced recycling processing contracts that allow each party to navigate volatile market conditions and the ever-changing landscape of consumer packaging. With four out of every five MRFs operating under private ownership, and most curbside recycling programs run by public agencies, the success of these public-private contracts is foundational to the success of U.S. recycling.

Starting with RFPs: A “Best Value” Approach

While local governments have many options for procuring MRF processing services, a Request for Proposals (RFP) process allows the most flexibility and transparency to both proposers and the community. Also known as a “best value” approach, an RFP is versatile in allowing a wide exploration of varying service parameters from different companies and is not just based on price alone.

RFPs also allow communities to take time to reflect on local goals and objectives, while involving critical internal stakeholders, including budget, purchasing, legal, and elected officials.

Among the critical decisions in the RFP process is determining what role the community should play – such as owning the land, building, and/or equipment related to a facility – and determining the length of the contract. Local purchasing offices often prefer shorter contracts (three years or less), in part to regularly test the market. But this approach runs counter to the realities of MRF companies, which will make large investments in expensive equipment that must show a return. Longer MRF contracts (seven to 10 years) better align with the amortization schedules that support best-in-class sorting capital. Renewal clauses also allow communities to sustain a good working relationship with their MRF in lieu of another RFP process.

11 Essential Elements of the Best MRF Contracts

These 11 essential elements of MRF contracts can help all communities address the most critical details of the business relationship:

- Processing Charges – Commodity pricing reflected in the “blended value” of sold materials no longer financially supports the full cost of MRF operations, making processing charges a necessity that should be called out directly and specifically in an RFP.

- Revenue Sharing – Many contracts have processing charges cover MRF costs, including, in many cases, a base level of profit. All MRF RFPs and contracts should address if and to what degree revenue is shared, separate from processing charges.

- Material Value Determination – If revenue sharing is included, contracts should explicitly identify mutually acceptable and transparent sources for determining commodity values.

- Acceptable Material Mix – Every MRF contract should have clarity around acceptable materials, while also detailing procedures and conditions under which the material mix might change.

- Material Audits – Contracts should make sure to include plans for regular audits and to spell out the frequency, focus, and protocols for assessing inbound and outbound material.

- Contamination and Material Quality – Contracts should include mutually agreed-upon contamination standards, which set the stage for community action on inbound material quality.

- MRF Performance – Contracts should convey clear and specific standards around the processing and marketing of delivered commodities.

- Rejected Loads and Residue Disposal – Contracts should include explicit parameters on what constitutes unacceptable loads, how they are handled, and how MRF residues are managed.

- Education and Outreach Support – As an increasingly important funding source for community education that drives high material tonnage and quality, contracts should define education-focused responsibilities and provide resources to support these efforts.

- Contingencies – Contracts should spell out plans for managing materials during a weather event or other service disruption.

- Reporting and Communications – The processing business relationship works best with regular information sharing between the contracting parties. Contracts should detail specific mechanisms for consistent and robust communication.

While MRF processing-services contracts have been in play for years, market conditions since 2018 have created an apparent “new normal” in these partnerships, with implications for both the ability of MRFs to remain viable and for community programs to be sustained. This underscores the urgency of applying best practices in MRF contracts now, so that they may continue to operate in synergy and success for years to come.

To get started on creating a strong and resilient MRF contract, Download the full guide for more information.

About the Authors

Scott Mouw, Senior Director of Strategy and Research

Scott brings extensive experience in taking a systems approach to recycling. In his previous role as North Carolina’s State Recycling Director, Scott led efforts in fostering local collection programs, implementing recycling policy, and building a recycling economy. Scott joined The Recycling Partnership to deploy the same lessons of success to the national scale. Core to this work has been understanding the nuances of each material, the nature of recovery economics and markets, and the necessary role of metrics and data in creating a resilient and responsive recycling system. Whether it’s the fine points of curbside collection, the basic MRF business model, or understanding how the supply of available material reacts to market demand, Scott is ready to engage with all stakeholders across the recycling spectrum.

Liz Bedard, Senior Director of Industry Collaboration, The Recycling Partnership

Liz has worked in the recycling and solid waste management field for more than 45 years, bringing extensive experience in innovative problem-solving and expert facilitation to The Recycling Partnership. In her previous role as Director of the New Hampshire Governor’s Recycling Program, she successfully developed statewide municipal, business, and school recycling programs. She also founded and served twice as Executive Director of the Northeast Resource Recovery Association, the oldest and largest recycling cooperative in the U.S., and previously worked as Director of the Association of Plastic Recyclers Olefins Division. Through her professional roles, board memberships, and previous position as a Selectman for a town in New Hampshire, Liz has developed a keen understanding of dynamics at the local, state, and regional level that can help improve recycling efforts. She currently serves as Senior Director of Industry Collaboration at The Partnership, where she works closely with stakeholders from all industries related to recycling.

Leave a comment