The Real Cost of Inaccuracy in Waste & Recycling

April 14, 2022

Inaccurate scales cost the waste & recycling industry thousands each year

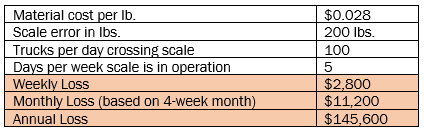

When material is purchased or sold based on weight, it is imperative that the scale being used to measure that weight produces accurate results. A scale that is producing inaccurate readings could lead to thousands of dollars in losses. Let’s illustrate the potential losses associated with an inaccurate scale in the example below.

Imagine a truck scale is used at the entrance to a landfill to charge $55.36* per ton (or $0.028 per lb.) for materials entering the facility. Upon inspection, the scale is 200 lbs. out of tolerance and has been weighing light. For every 200 lbs. not being weighed, the landfill is losing four dollars. If there are 100 trucks weighing in on this scale every day, five days per week, the inaccuracy could cost the landfill $104,000 each year.

Visit our website and use our inaccuracy cost calculator where you can enter your own figures to determine how much you could be losing due to an inaccurate scale.

* Per EREF releases analysis on national landfill tipping fees, October 29, 2019

How can facilities ensure accuracy?

Preventative maintenance and regular inspections are the keys to ensuring accuracy. While many people understand the importance of proper maintenance, it’s easy for these tasks to get overlooked. By instituting a preventative maintenance plan, facilities can minimize inaccuracy and keep equipment in great working order. In addition, regular inspections by a certified calibration technician with certified test weights are the best way to ensure scales remain in tolerance.

Preventative Maintenance Tips

- Regularly clean the scale to remove dirt and debris from the scale deck, entrance/exit ramps, and underneath the scale to ensure proper functionality.

- Establish a preventative maintenance schedule and stick to it. By prioritizing preventative maintenance, operators can minimize unplanned downtime for repairs.

- Utilize a quality service provider to perform regular inspections. After the inspection, ask the service technician if there are any additional steps operators can take between inspections to help ensure accuracy.

- The service provider should utilize a standard, repeatable inspection method based on Handbook 44.

- The service technicians should be state certified.

- The test weights used during the inspection should be certified.

How Michelli Weighing & Measurement Can Help with Preventative Maintenance?

The Michelli Weighing & Measurement team provides preventative maintenance agreements to help keep the waste & recycling industry scales running smoothly. These agreements allow Michelli customers to establish a preventative maintenance schedule (including preferred days and times for service), lock in service rates, and obtain discounts on replacement parts if needed. Preventative maintenance agreements help Michelli customers keep up with maintenance-related activities without interrupting operations.

Track Assets for Planning Purposes

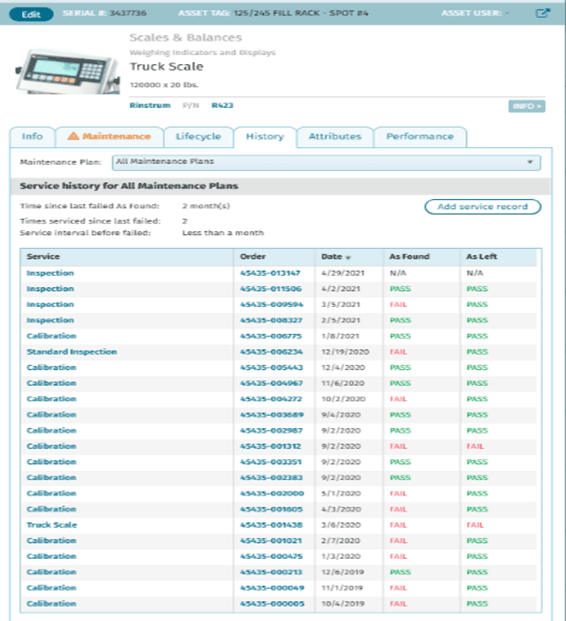

Another benefit to instituting a preventative maintenance plan is that it allows facility managers to keep up with the status of their assets. Going one step further, utilizing an asset management system could allow managers to schedule downtime for service, identify patterns with faulty equipment, and forecast future equipment purchases.

Asset management also allows users to monitor their maintenance schedules & increase or decrease scale service as needed. For example, if bimonthly scale inspections have not uncovered any glaring inaccuracies, perhaps the operator could reduce inspection frequency.

Also, asset tracking allows facility managers to identify patterns with problematic equipment. For example, it’s easy to see if certain scales are repeatedly found out of tolerance during inspections. This allows managers to plan for equipment replacement and budget accordingly.

How Michelli Weighing & Measurement Can Help with Asset Management

All Michelli Weighing & Measurement customers get free access to TRAC, our asset management software. “TRAC” enables users to Track Records, Assets & Calibrations. TRAC houses all customer service records in one database that is accessible 24/7. It also allows users to keep up with the status of their equipment, identify patterns, and request service with just a few clicks.

By taking a few simple steps to ensure accuracy between scale inspections, facility managers could save thousands. Preventative maintenance is much more affordable than repairs. It also helps managers avoid unnecessary losses. Contact Michelli Weighing & Measurement today to learn more about how our team of service experts can help ensure your scales are producing accurate results. With 29 locations in 11 states, we are always nearby and ready to help.

Author:

Bobby Feigler

General Manager

Michelli Weighing & Measurement

504-275-7789

bfeigler@Michelli.com

www.michelli.com

800-903-8823

info@michelli.com

Leave a comment