Maximizing Landfill Gas Returns – Getting your site ready for a beneficial use project

May 25, 2022 by Tom Bilgri and Dave Knapp

Developing an LFG beneficial-use facility can protect the environment and improve human health while offsetting rising operating costs by generating revenue. To be successful, carefully contemplate the financial commitments and operational changes that might be involved and take steps to minimize costs and maximize revenue.

Operational considerations for recovery projects

The operation of your LFG system is critical in meeting your project goals. The key to ensuring effective gas system operation is understanding your data objectives and the art of wellfield tuning. Operational considerations for any recovery project include:

- Optimize methane recovery

- Minimize oxygen and nitrogen intrusion

- Do not rush; be patient during extraction

- Recover more gas sooner with interim collection

Good data is the key to any successful project

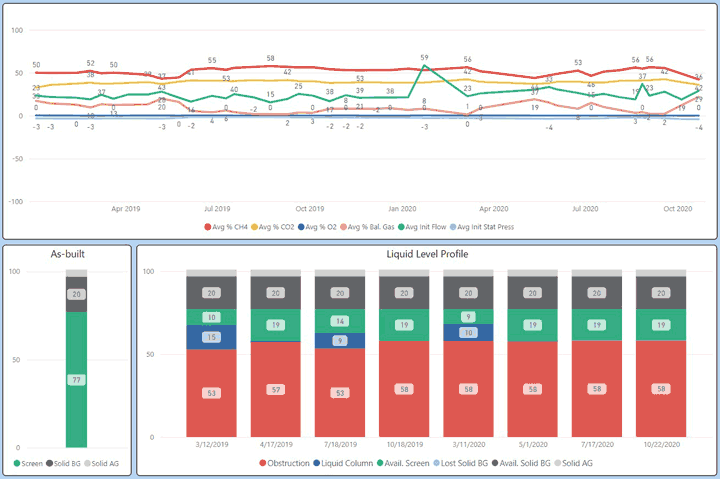

Operators must conduct data analyses and trend evaluations to uncover issues and problems that may not have been evident during design and to account for any seasonal changes. Consider use of 3D modeling for gathering data.

Wellfield assessment considerations

The goal of an LFG collection system is early LFG collection and optimization of fuel delivery. Improve gas quality by using low-permeability cover soils and temporary flexible membrane liner covers. Carefully consider design of collectors, spacing and size.

Consider these three factors when evaluating a wellfield:

Gas system age

GCCS age can have an impact on operations. Older portions of the system can often be buried quite deeply as additional waste materials are placed. This may lead to differential settlement of the header or structural deformation/failure.

Collector well spacing

Vertical wells are typically spaced 200-300 feet apart for control purposes, while utilization purposes may call for spacings of less than 200 feet. Horizontal wells are typically installed several hundred feet apart and 4-6 feet deep for control purposes; for utilization purposes one may see spacings closer, but at distances to prevent short-circuiting.

Liquids management

Whether preparing for a recovery project or just designing a landfill, liquids can be a significant impediment to gas generation and recovery. Take the time to develop liquid level trends to correlate with LFG recovery trends but be prepared to address liquids continuously. While liquids are necessary to circulate nutrients and bacteria for decomposition, too much liquid can inhibit the ability to effectively remove the LFG produced. Properly done, liquid level reduction can increase both gas quantity and quality.

Compliance and regulatory changes

Organics legislation is coming. However, these changes may result in new opportunities. Prohibition of organic materials in landfills, from yard waste to food waste, can potentially cut into the landfill owner’s gate receipts and LFG utilization revenue. However, landfill owners who set up their own anaerobic digestion (AD) or composting operations get to keep the food waste intake/revenue they currently have.

Setting up an AD will reduce LFG generation from the landfill but will provide another source of high-quality biogas from the AD that can be utilized. Be aware of any space and infrastructure requirements for an organics project, including space for a flare, site access, and access for equipment, construction, waste materials, and operating supplies. Also consider water, sewer, waste disposal, communications, electrical service, and gas treatment costs.

Ask the right questions to prepare for success

Be sure to review data trends, wellfield density and availability of perforations, as well as cover integrity. Being proactive will result in more and better fuel earlier on the site life. Also, carefully consider spatial and utility needs. Be aware of potential pitfalls that may lead to lost revenue. Knowing who to ask and the right questions to ask are the first steps in developing a successful project.

Author bios

Tom Bilgri, P.E., manages Tetra Tech’s Biogas Engineering Services group. He has more than 30 years of experience in LFG management system engineering and has worked on developing beneficial-use projects, including direct sale, electrical generation and compressed natural gas (RNG) production facilities. He chairs the LFG/Biogas Technical Division Program Committee of the Solid Waste Association of North America.

David Knapp works with Tetra Tech’s Solid Waste Solutions group to grow, develop, and manage projects in Georgia and throughout the Southeastern United States. He specializes in LFG management, utilization, and compliance. In addition, he serves as program manager and technical leader for various aspects of LFG to energy construction management and environmental service markets, including design oversight and review, due diligence, environmental support, municipal, and major solid waste initiatives with public and private clients.

This blog is based on an article that originally ran in MSW Management Magazine.

Leave a comment